Silicon nitride riser

Silicon nitride ceramic can help customers to make high quality die casting parts owe to its inertness against molten aluminum.

Category:

key word:

Silicon nitride ceramic

Service Hotline:+86-18074820425

Consult NowProduct Description

Data sheet

|

Items |

Unit |

Model |

|

|

|

|||

|

Z-200 |

Z-500 |

||

|

Bulk density |

g/cm3 |

3.2 |

3.2 |

|

Water absorption |

% |

0 |

0 |

|

Bending strength |

MPa |

750 |

800 |

|

Young modulus |

Gpa |

280 |

290 |

|

Fracture toughness |

MPa ·m1/2 |

6.5 |

7 |

|

Poisson's ratio |

一 |

0.28 |

0.28 |

|

Vickers hardness |

Gpa |

15 |

15 |

|

Coefficient of linear expansion |

x10-6/°C |

3.4 |

3.5 |

|

Thermal conductivity |

W/(m ·k) |

26 |

50 |

|

Specific heat |

J/(g ·k) |

0.65 |

0.61 |

|

Volume resistivity |

Ω·cm |

>10¹⁴ |

>10¹⁴ |

|

Heat shock resistance |

℃ |

800 |

900 |

|

Maximum operation temperature |

℃ |

1150 |

1150 |

Advantage OF SILICON NITRIDE:

◆ Silicon nitride ceramic can help customers to make high quality die casting parts owe to its inertness against molten aluminum.

◆ Silicon nitride ceramic can help customers to make high quality die casting parts owe to its inertness against molten aluminum.

◆ Compare with cast iron, the silicon nitride ceramic is light, it makes handling easy, help customers to reduce the work intensity.

◆ Help to ensure the stable quality of die casting parts

Typical application:

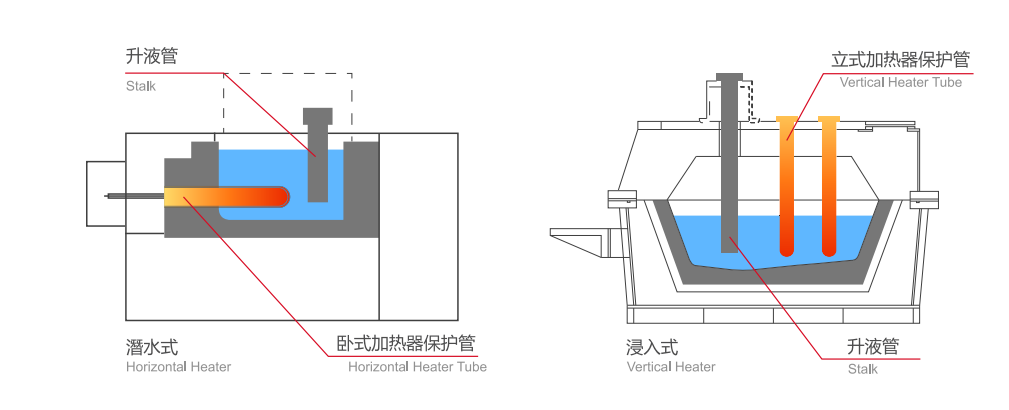

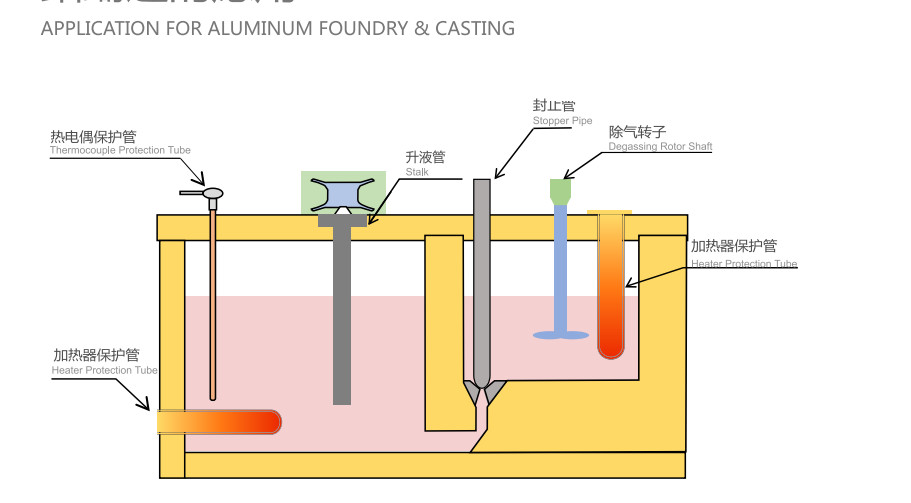

HEATER PROTECTION TUBE

We use submergible heating element and heat source is in the centre of aluminum solution.So we have great heat-transfer performance which can save more energy consumption than traditional heating methods.Aluminum Solution at the top of the kiln will not be oxidated because of overheated.As thus,the loss of aluminum will be lower,the quality of aluminum casting parts will be better,at the same time,the damage due to residue of aluminum dregs in the kiln wall will be reduced.

STOPPER PIPE

Silicon nitride ceramic has high density and abrasion resistance, it is most suitable material used for low pressure die casting. The stopper pipe has the most favorable properties of protectiveness, impermeability and excellent precision.

The life time of the stopper pipe can be used for many years if keeping regular maintenance.Otherwise, incorrect operation and less attention to a maintenance will reduce the life time.

THERMOCOUPLE PROTECTION TUBE

Silicon nitride ceramic has the best thermal conductivity when used for aluminum melting,lts quickly response to the temperature sensor in aluminum and other nonferrous metals melting.Excellent shock resistance and lightweight make it easier to operate and maintain,moreover,it can be used for many years

|

Length |

|

|

|

200 |

28 |

16 |

|

300 |

28 |

16 |

|

350 |

28 |

16 |

|

400 |

28 |

16 |

|

450 |

28 |

16 |

|

500 |

28 |

16 |

|

600 |

28 |

16 |

|

700 |

28 |

16 |

|

800 |

28 |

16 |

|

900 |

28 |

16 |

|

1000 |

28 |

16 |

|

1100 |

28 |

16 |

|

1200 |

28 |

16 |

STALK FOR LOW PRESSURE DIE CASTING

Comparing with cast iron materials,silicon nitride riser tube for low pressure die casting has low heat conduction,its super heat preservation can prevent the temperature reducing of aluminum solution in low pressure casting.We use the way of GPS to get high density,which makes it possible to keep high mechanical strength when temperature rises. lt will reduce the risk of air leakage and damage if load and strength are weak It is not easy to adhere aluminum, so it makes daily maintenance more convenient.

|

|

|

|

|

|

|

820 |

87 |

72 |

95 |

20 |

|

880 |

87 |

72 |

140 |

130 |

|

800 |

145 |

125 |

175 |

190 |

|

1040 |

188 |

169 |

200 |

15 |

|

1050 |

170 |

150 |

190 |

14 |

|

1250 |

170 |

150 |

190 |

20 |

|

1250 |

112 |

96 |

152 |

190 |

|

1250 |

155 |

135 |

193 |

163 |

DEGASSING ROTOR

Nitride ceramic rotor shaft exhibits exceptional wear and oxidation resistance compared to a graphite rotor. lt assures stable high hydrogen removal efficiency for a long service life.and it can reduce the frequency of replacing new parts, so that help customer have good cost savings.The impeller structure design of rotor shaft, help the gas spreading evenly in the aluminum solution, at the same time, reduce the gas into the solution, prevent the whirlpool shaped.The high gas dispersibility makes hydrogen removal efficiency superior, as a result, improve the quality of die casting parts.

REFING TUBE COMPONENTS

Silicon nitride ceramic has the excellent corrosion resistance,the best mechanical strength and excellent thermal shock resistance.lt is the most important component when being used for melting aluminum.

Silicon nitride ceramic has replaced the past metal materials increasingly.

It has long lifetime and it can help customer to lower production cost,raises products quality.

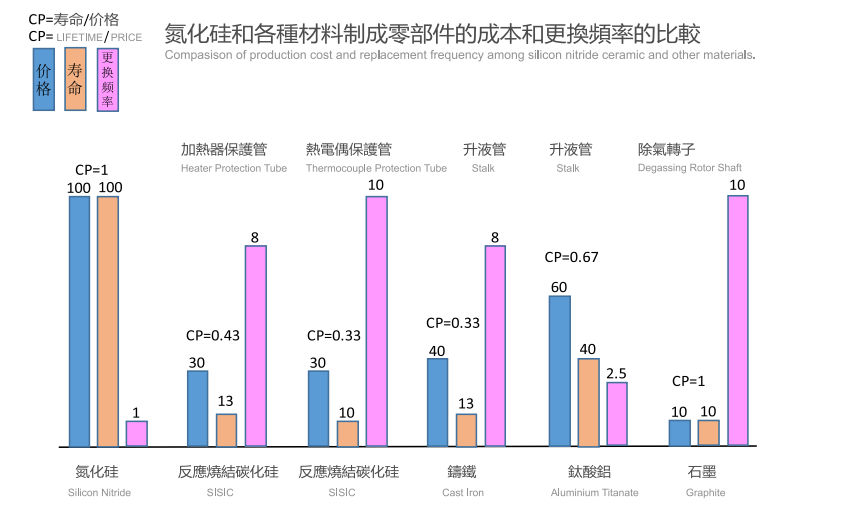

Compasison of production cost and replacement frequency among silicon nitride ceramic and other materials.

ATTENTION

It should be preheated before heating the cold kiln.

It should be preheated before heating the cold kiln.

It should be cooled and heated gradually, avoid fast cooling and heating.

It should be handled with care, avoid beating by sharp objects.

The end of heater must be immersed into the aluminum solution when heating,it should avoid dry heating.

To avoid leaking,elastic gasket with high temperature resistance should be selected when installing the flange.

Keep regular cleaning and maintenance can prolong the service time,otherwise,the life time will be shorter.

When installing the degassing rotor shaft,make sure every bolt is fastened tightly so that avoiding the bolt loose.

Related products

A plate-type holding furnace is used for holding the temperature of molten aluminum during metal die casting.

Bath Type Low Pressure Casting Holding Furnace

Bath Type Low Pressure Casting Holding Furnace Equipment Characteristics ◆ The furnace body bears high pressure and high strength. The furnace shell is welded by high strength steel plate. When the test pressure is 0.25 MPa, there is no deformation on the shell. ◆The sealing performance of the furnace body is great. The furnace cover, door and rod connection are reliably sealed with the furnace body, and there is not gas leaks. ◆ No crucible loss. Non-metallic aluminium melt pool, no crucible loss, low use and maintenance costs. ◆ Liquid aluminum does not increase iron. Non-metallic molten pool, aluminum liquid without iron hyperplasia and other pollution. ◆ The melt pool has a long service life. The molten pool is casted with low cement castable for aluminum alloy, which is resistant to aluminum liquid erosion and has a service life of more than 3 years. ◆ Good insulation performance. The lining insulation adopts high-quality insulation materials such as silicon-calcium plate and nano-plate, and the temperature rise of the furnace shell surface is less than 60 °C. ◆ High temperature control precision. With the intelligent temperature control instrument and aluminum temperature thermocouple, the double loop control of aluminum liquid and furnace temperature is realized, and the temperature control accuracy reaches ± 2℃.

Bath Type Melting Furnace Equipment Features ◆ The molten pool is formed by integral injection molding with non-infiltrative and high-strength injection-resistant material (Allied Mineral), and the molten pool does not adhere to aluminum, which slows down the formation of corundum tumor. ◆ Non-metallic molten pool, liquid aluminum without iron hyperplasia and other pollution. ◆ The melt hearth service live is more than 3 years. ◆ The furnace village adopts multi-layer anti-leakage technology, without the consideration of aluminum liquid ' string leakage ' lining. ◆ The furnace cover has a cylinder rotating lift, which is convenient for molten pool cleaning, slag removal operation, furnace cover and electric heating element maintenance. ◆ It has a variety of safety protection such as aluminum liquid over-temperature alarm and furnace over-temperature alarm.

Count Pressure Casting Holding Furnace

Count Pressure Casting Holding Furnace The electrical type counter pressure furnace is made of high-quality electrical resistance wire as heating element. The furnace lining is composed of fiber module and fiber blanket, which has less heat storage and good heat preservation performance. The crucible furnace is suitable for graphite crucible. The crucible has good high temperature oxidation resistance and can be used for melt insulation before differential pressure casting. The crucible furnace is equipped with a power plug, which can be conveniently, safely and reliably connected with the power socket on the counter pressure casting machine.

MESSAGE

We will contact you within one working day. Please pay attention to your email.