Rotary Flux Injector for Molten Aluminium Refining

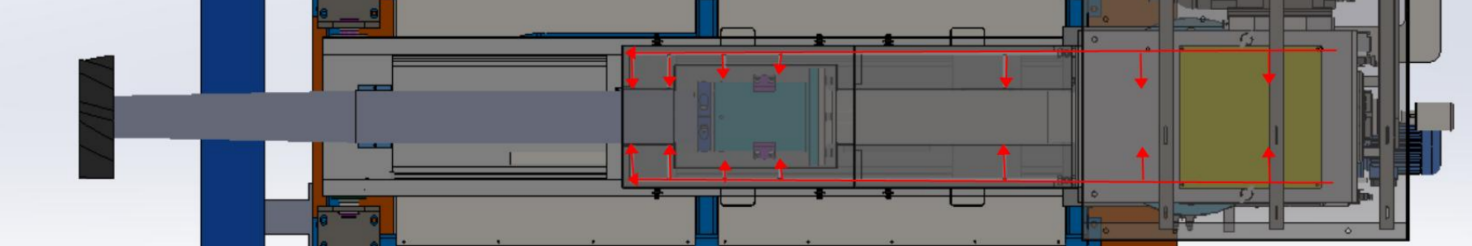

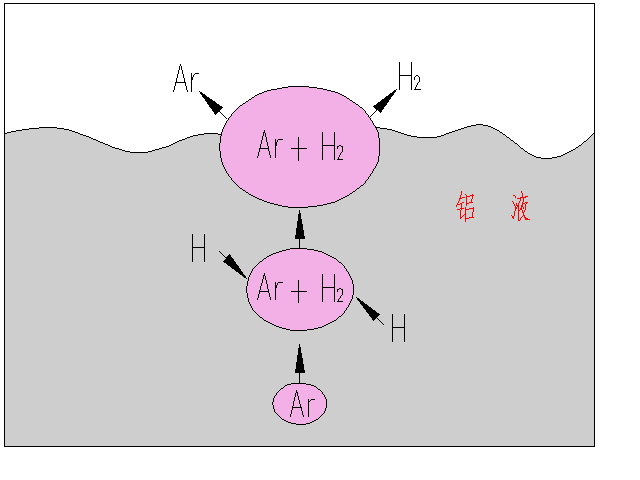

The Rotary Flux Injector is used beside the furnace wall. And for degassing and fluxing inside the furnace to improve the quality of the molten. It can be used for two furnaces once the layout is okay.

key word:

Service Hotline:+86-18074820425

Consult NowProduct Description

- EQUIPMENT FEATURES

Rack

- The rack is made of rectangular tubes and welded steel plates. The frame structure must ensure stability, firmness, and good rigidity.

Mobile Traveling Mechanism

- The traveling mechanism of the mobile box includes rollers, mobile box, guide rails, chain transmission, and other parts. The suspension bolt is connected to the mobile box, and the chain drives the mobile box. The mobile box is equipped with rollers, which rotate on the guide rail.

- The walking guide rail is made of heavy-duty channel steel, and the walking roller adopts a composite roller with bidirectional positioning. The bidirectional positioning between the roller and the guide rail ensures that the rotary refining device on the furnace side can move flexibly, smoothly, and without swinging; The internal bearing of the roller is a self-lubricating bearing, which is free from maintenance during equipment operation; This configuration of walking rails and rollers ensures the reliable operation of the furnace side rotating refining device in high-temperature and dusty casting sites.

- The electric motor, worm gear reducer, and chain sprocket form a chain transmission system to complete the movement of the mobile box; Select a worm gear reducer with good self-locking performance to ensure that the mobile box stops at any position within the walking range.

- The travel range of the mobile box is adjustable. Limit switches are installed at the front and rear limit positions of the mobile box to ensure reliable limit of the mobile box; The limit switch is installed inside the formed slide rail, which can conveniently adjust the travel limit position of the mobile box.

Trolley Travel System

- The equipment sits on a small car as a whole, which drives the equipment to rotate and walk, determining the refining position, and thus achieving refining and degassing in the furnace for two sets furnaces.

Rotor Rotary System

- The spindle rotation system includes rotating spindle box, spindle, rotating motor, pulley transmission system, and other parts.

- The spindle bearing is installed in the spindle box, which adopts a high-temperature resistant design to ensure that the spindle box can work continuously under high temperature radiation; The outer surface of the spindle box is coated with silicone high-temperature paint, the spindle is subjected to high-temperature quenching and tempering treatment, the bearings are high-temperature bearings, and the lubricating grease is high-temperature lubricating grease

- The belt transmission system composed of an electric motor, a pulley, and a triangular belt ensures convenient adjustment and smooth transmission.

- The rotating spindle is finely processed through cylindrical grinding, and the maximum radial runout during the highest speed rotation is not greater than 0.1mm (measured at the rotor chuck)

Spindle Insulation Board

- When the equipment is working, it protects the metal spindle and reduces heat intrusion;

Cooling System

- External compressed air cooling;

- Circlulating heat dissipation design;

- Protection bearings;

- High temperature resistant graphite rod looseness;

Fluxing Feeding System

|

The rotary refining device on the furnace side is equipped with one set of powder adding device. The fluxing supply system adopts a rotating wheel for feeding, which can be used for conveying powder with a maximum diameter of 3mm. All powder supply components in contact with the powder are made of corrosion-resistant 316 stainless steel; An observation mirror is installed on the flux powder cylinder.

Previous:

Related products

A plate-type holding furnace is used for holding the temperature of molten aluminum during metal die casting.

Bath Type Low Pressure Casting Holding Furnace

Bath Type Low Pressure Casting Holding Furnace Equipment Characteristics ◆ The furnace body bears high pressure and high strength. The furnace shell is welded by high strength steel plate. When the test pressure is 0.25 MPa, there is no deformation on the shell. ◆The sealing performance of the furnace body is great. The furnace cover, door and rod connection are reliably sealed with the furnace body, and there is not gas leaks. ◆ No crucible loss. Non-metallic aluminium melt pool, no crucible loss, low use and maintenance costs. ◆ Liquid aluminum does not increase iron. Non-metallic molten pool, aluminum liquid without iron hyperplasia and other pollution. ◆ The melt pool has a long service life. The molten pool is casted with low cement castable for aluminum alloy, which is resistant to aluminum liquid erosion and has a service life of more than 3 years. ◆ Good insulation performance. The lining insulation adopts high-quality insulation materials such as silicon-calcium plate and nano-plate, and the temperature rise of the furnace shell surface is less than 60 °C. ◆ High temperature control precision. With the intelligent temperature control instrument and aluminum temperature thermocouple, the double loop control of aluminum liquid and furnace temperature is realized, and the temperature control accuracy reaches ± 2℃.

Bath Type Melting Furnace Equipment Features ◆ The molten pool is formed by integral injection molding with non-infiltrative and high-strength injection-resistant material (Allied Mineral), and the molten pool does not adhere to aluminum, which slows down the formation of corundum tumor. ◆ Non-metallic molten pool, liquid aluminum without iron hyperplasia and other pollution. ◆ The melt hearth service live is more than 3 years. ◆ The furnace village adopts multi-layer anti-leakage technology, without the consideration of aluminum liquid ' string leakage ' lining. ◆ The furnace cover has a cylinder rotating lift, which is convenient for molten pool cleaning, slag removal operation, furnace cover and electric heating element maintenance. ◆ It has a variety of safety protection such as aluminum liquid over-temperature alarm and furnace over-temperature alarm.

Count Pressure Casting Holding Furnace

Count Pressure Casting Holding Furnace The electrical type counter pressure furnace is made of high-quality electrical resistance wire as heating element. The furnace lining is composed of fiber module and fiber blanket, which has less heat storage and good heat preservation performance. The crucible furnace is suitable for graphite crucible. The crucible has good high temperature oxidation resistance and can be used for melt insulation before differential pressure casting. The crucible furnace is equipped with a power plug, which can be conveniently, safely and reliably connected with the power socket on the counter pressure casting machine.

MESSAGE

We will contact you within one working day. Please pay attention to your email.