Regenerative Gas Fired Melting and Holding Crucible Furnace

Regenerative Gas Fired Melting & Holding Crucible Furnaces are used for efficient melting of Aluminium,

Category:

key word:

Crucible Furnace

Regenerative Gas Fired

Service Hotline:+86-18074820425

Consult NowProduct Description

Regenerative Gas Fired Melting and Holding Crucible Furnace

Regenerative Gas Fired Melting and Holding Crucible Furnace

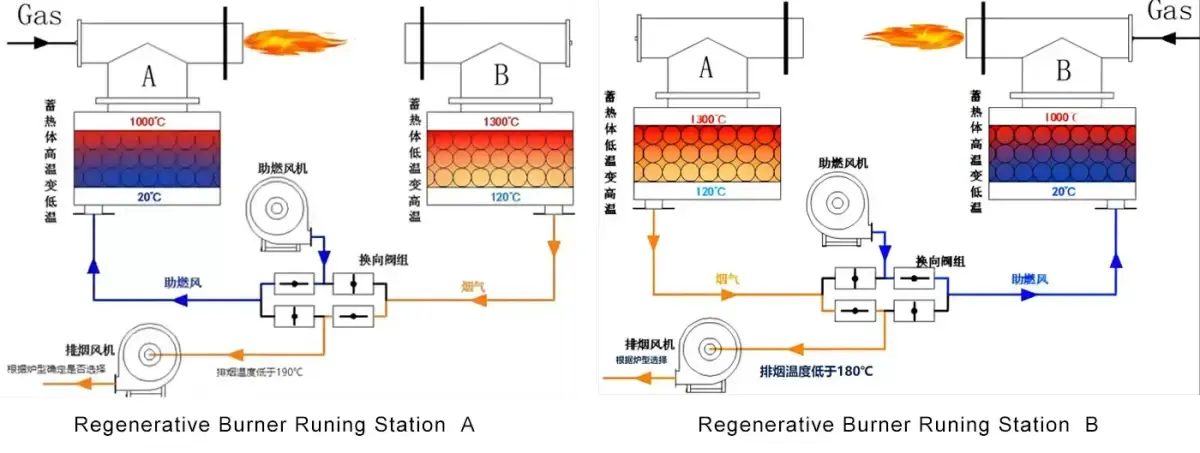

Regenerative Gas Fired Melting & Holding Crucible Furnaces are used for efficient melting of Aluminium, Aluminium chips, and Aluminium slags. The furnace is equipped with dual burners and a heat storage box. With the control system, it can automatically switch the burner to burn, increase the flame temperature, reduce the gas consumption, and reduce the exhaust gas temperature to within 180°C, which can greatly reduce energy consumption and improve the working environment.

Feature

◆ High efficiency and save energy. The gas consumption for melting 1T of aluminium is less than 55m³ natural gas, which saves energy by more than 30% compared with ordinary gas-fired crucible furnaces.

◆ Low exhaust gas temperature. The exhaust gas heat is fully recovered and utilized, and the exhaust gas temperature can be as low as 180℃.

◆ High melting rate. One furnace can be melted in about 2 hours under the state of hot furnace.

◆ Flexible usage. The regenerative furnace uses crucibles to melt aluminium, and the crucibles can be replaced according to different grades of aluminium alloys. Compared with the centralized/castble melting furnace, it has a wide range and flexible usage, and is suitable for small batches of aluminium alloy casting.

Burner System

◆ The burner system is composed of burner, heat storage box, ignition burner, fan, reversing mechanism, pipelines and other parts.

◆ There are small gas pipelines around the burner, the gas supply is even, and the combustion is more sufficient. The inside of the burner is knotted with refractory material, which is resistant to flame impact and has a long service life.

◆ The thermal storage box consists of outshell, thermal insulation material, thermal storage body and other parts. Insulation materials are set around the outshell to lock the temperature to the maximum extent and improve the utilization rate of exhaust gas. The thermal storage body adopts honeycomb ceramic heat storage bricks with excellent performance, which has strong heat storage capacity, high temperature resistance and is not easy to be pulverized.

◆ The ignition burner adopts the finished burner. The failure rate is low, and the installation method adopts the quick pressing structure, which is convenient for disassembly and assembly.

◆ The reversing mechanism adopts a linkage design. There is no impact when the burner is switched, the transition is stable and it is not easy to flame out. There is no aging gasket inside, so there is no need to disassemble and replace the gasket.

Technical Parameters

|

Item |

Name |

Data |

Remark |

|

|

1 |

Efficient Capacity |

600-1200 |

|

|

|

2 |

Melting Rate |

300-600 |

|

|

|

3 |

Gas Consumption |

≥55 |

|

|

|

4 |

Max. Furnace Hearth Temperature |

1000 |

|

|

|

5 |

Temperature Control Method |

Double Temperate Control |

Molten Aluminium & Furnace Hearth |

|

|

6 |

Temperature Control Accuracy |

±5 |

|

|

|

7 |

Gas |

Gas Type |

Natural Gas |

|

|

KPaGas Pressure |

5 |

|

||

|

Max. Flow Rate m³/h |

45 |

|

||

|

Note: The melting rate refers to the state of the hot furnace (the furnace temperature is not lower than 850℃, the remaining molten aluminium in the crucible is not less than a quarter of the crucible capacity, and the temperature of the molten aluminium is not lower than 650℃). When the temperature of molten aluminium rises to 660℃, the mass of aluminium is melted in an average of 1 hour. |

||||

Related products

A plate-type holding furnace is used for holding the temperature of molten aluminum during metal die casting.

Bath Type Low Pressure Casting Holding Furnace

Bath Type Low Pressure Casting Holding Furnace Equipment Characteristics ◆ The furnace body bears high pressure and high strength. The furnace shell is welded by high strength steel plate. When the test pressure is 0.25 MPa, there is no deformation on the shell. ◆The sealing performance of the furnace body is great. The furnace cover, door and rod connection are reliably sealed with the furnace body, and there is not gas leaks. ◆ No crucible loss. Non-metallic aluminium melt pool, no crucible loss, low use and maintenance costs. ◆ Liquid aluminum does not increase iron. Non-metallic molten pool, aluminum liquid without iron hyperplasia and other pollution. ◆ The melt pool has a long service life. The molten pool is casted with low cement castable for aluminum alloy, which is resistant to aluminum liquid erosion and has a service life of more than 3 years. ◆ Good insulation performance. The lining insulation adopts high-quality insulation materials such as silicon-calcium plate and nano-plate, and the temperature rise of the furnace shell surface is less than 60 °C. ◆ High temperature control precision. With the intelligent temperature control instrument and aluminum temperature thermocouple, the double loop control of aluminum liquid and furnace temperature is realized, and the temperature control accuracy reaches ± 2℃.

Bath Type Melting Furnace Equipment Features ◆ The molten pool is formed by integral injection molding with non-infiltrative and high-strength injection-resistant material (Allied Mineral), and the molten pool does not adhere to aluminum, which slows down the formation of corundum tumor. ◆ Non-metallic molten pool, liquid aluminum without iron hyperplasia and other pollution. ◆ The melt hearth service live is more than 3 years. ◆ The furnace village adopts multi-layer anti-leakage technology, without the consideration of aluminum liquid ' string leakage ' lining. ◆ The furnace cover has a cylinder rotating lift, which is convenient for molten pool cleaning, slag removal operation, furnace cover and electric heating element maintenance. ◆ It has a variety of safety protection such as aluminum liquid over-temperature alarm and furnace over-temperature alarm.

Count Pressure Casting Holding Furnace

Count Pressure Casting Holding Furnace The electrical type counter pressure furnace is made of high-quality electrical resistance wire as heating element. The furnace lining is composed of fiber module and fiber blanket, which has less heat storage and good heat preservation performance. The crucible furnace is suitable for graphite crucible. The crucible has good high temperature oxidation resistance and can be used for melt insulation before differential pressure casting. The crucible furnace is equipped with a power plug, which can be conveniently, safely and reliably connected with the power socket on the counter pressure casting machine.

MESSAGE

We will contact you within one working day. Please pay attention to your email.