LA-MV Intelligent Transfer Ladle and Pouring System

Category:

key word:

Service Hotline:+86-18074820425

Consult NowProduct Description

01 Market Challenges

Why choosing LvGong Intelligent ?

●Occupational Safety

●Total Productive Management (TMP)

●Innovative materials

●Innovative Technology

●Sustainability

●Compliance with Environmental Regulations

02 Further development and advantages

Safety First! Further development and advantages

1.Occupational safety

• Schnorkle does not need to be tilted for metal transfer

• Low lifting height of the lift truck

• No spilling during transfer with the

• lift truck (Emergency Stop)

• Closed system

2.Control

• Automatic shut-off

• Alarm and information messages

3.Melt treatment

• The melt can be treated using an impeller

• Impeller positioned in centre.

4.Simple operation

• Fully automatic suction,Adjustable mass flow (two speeds at the push of a button)

• Constant mass flow

5.Aluminum liquid intake and output, vacuum technology, precise control

• Intake time:1.25min (Suction capacity of 1000kg)(Adjustable)

• Positive pressure: approximately 45-70 KPa

• Negative pressure: approximately 40- 55KPa

• Maximum aluminum suction lift: 2.4m

• Liquid level detection accuracy: +/-3mm

• Air storage tank capacity: 50 liters

• Air compressor storage capacity: 120 liters

6.High quality standards

•Reduced contact of the melt with the atmosphere

•No temperature loss thanks to the closed system

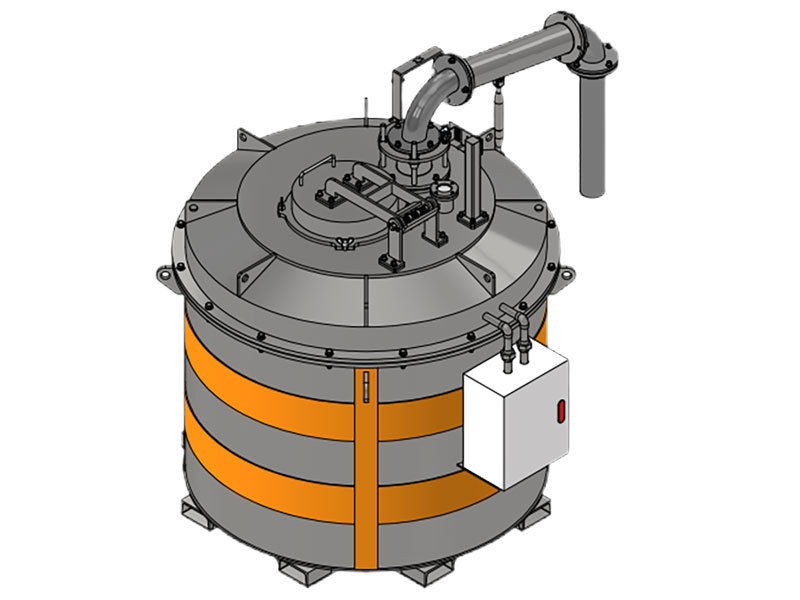

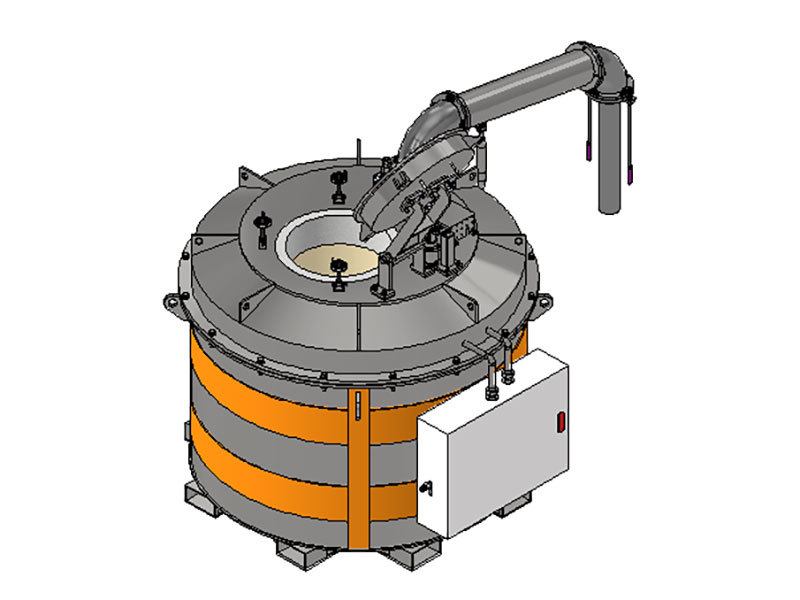

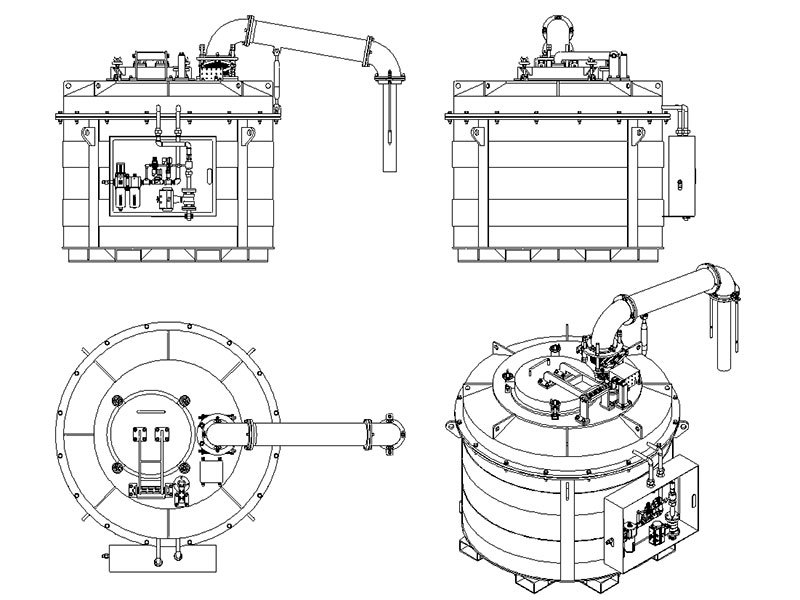

7.Design

Capacity:1000kg max

Aluminum liquid suction/push pipe diameter:Φ100 x Φ80mm

Package body dimensions: Φ1570 x H1360mm

Equipment dimensions:L2625 x H1850mm

Maximum aluminum liquid temperature: Maximum allowable temperature for the process

Mode of movement: Forklift or AGV

03.How It Works

• Equipped with its own negative pressure generation device, it utilizes the compressed air inside the AGV vehicle to create a certain degree of vacuum within the package, thereby suctioning the molten aluminum from the furnace into the package and transporting it to the quantitative furnace or holding furnace of the die-casting system.

• With the aid of the compressed air attached to the AGV vehicle, a positive pressure is generated within the package. The molten aluminum inside the package is then directly injected into the ladle channel or furnace of the holding furnace through the lift tube. This ensures that the contact area between the molten aluminum and the atmosphere is minimized, resulting in uniform feeding.

04.User friendly

1.Low maintenance requirements

• No pump

• No moving mechanical parts

2. Flexibility

• Can be used with all normal melting and dosing systems

• Can be integrated into existing production processes

3.versatility

• Can be used even when ceilings are low

• Transfer and dosing process can be synchronized (supply station as a future option)

• No overfilling (supply station as a future option)

4.Installation

• Extremely flexible

• 380 possible installation situations without design

05.Model sizes & ranges

Model ranges and sizes

Three sizes available

• LA-MV- 800

• LA-MV- 1000

• LA-MV- 1200

Total weights

• LA-MV- 800 : 2100 kg

• LA-MV- 1000 : 2500 kg

• LA-MV- 1200 : 2900 kg

Filling heights

• LA-MV- 800 = 1080 mm

• LA-MV- 1000 = 1360mm

• LA-MV- 1200 = 1530 mm

Comprehensive installation options

The installation position and direction of the outlet pipe can be adjusted according to the on-site equipment.

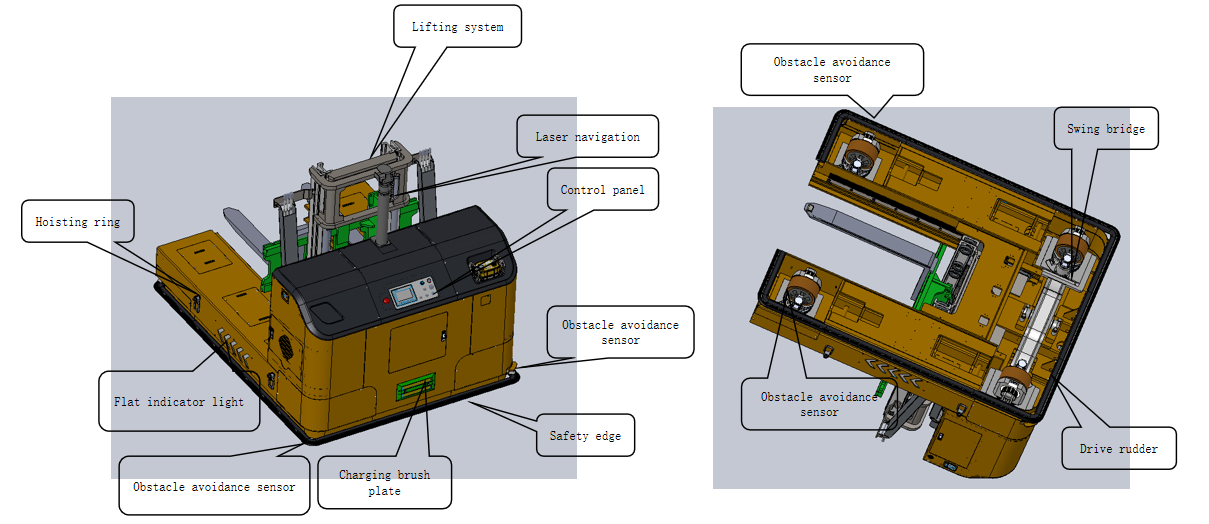

06.Introduction to AGV

No. | Item | Unit | design value | |

Overall machine characteristics | 1 | Navigation method | SLAM Laser SLAM | |

2 | Rated load | kg | 3500 | |

3 | Load center distance | mm | 650 | |

4 | Wheel type | Polyurethane | ||

5 | Front wheel specification | mm | Φ280 | |

6 | Service brake | electromagnetic brake | ||

7 | Driven wheel specification | mm | Φ280 | |

Dimensional parameters | 8 | Standard lifting height | mm | 3000 |

9 | Navigation height | mm | 2390 | |

10 | Fork specification | mm | 1300*150*50 | |

11 | Navigation method Aluminum liquid quantitative package capacity | kg | 1000 | |

12 | Diameter of aluminum liquid quantitative package | mm | 1400 | |

13 | Total length (excluding safety edges) | mm | 2450 | |

14 | Total width (excluding safety edges) | mm | 2200 | |

15 | Total height | mm | 2490 | |

16 | Net weight | kg | 5000 | |

Performance parameters | 17 | Traveling speed (empty/full load) | km/h | 2.8 |

18 | Lifting speed (empty/full load) | m/s | 0.26/0.23 | |

19 | Lowering speed (empty/full load) | m/s | 0.21/0.31 | |

20 | Maximum gradient (empty/full load) | ° | 3 | |

Battery | 21 | Battery type | Lithium-ion battery | |

22 | Continuous working time | h | 6 | |

23 | Battery cell life | 2000 | Full charge and full discharge | |

24 | Battery charging time | ≤2h |

Using the wheel drive mode as shown in the right figure; the walking motor is responsible for outputting the forward force of the entire AGV body, directly driving the drive wheel, and can meet the speed and power requirements of AGV walking; during walking, the walking encoder records the number of rotations, feeds back to the driver, and the driver feeds back to the AGV control system. The comparison and adjustment of the input value and the feedback value realize the precise walking control.

The walking motor is equipped with electromagnetic brakes, which can effectively perform braking. The steering motor is the motor that rotates when the AGV turns. Through gear transmission, the large gear is part of the rotating support. The large gear is fixed to the body, and the rotating part of the support is fixed to the walking motor and the drive wheel. That is, when the rotating motor operates, the lower part of the large gear rotates as a whole to achieve AGV steering. When rotating, the small gear on the steering encoder also rotates relative to the large gear. Through the ratio of large and small gears, the monitoring of angle rotation is realized, achieving precise steering.

Previous:

Next

Related products

A plate-type holding furnace is used for holding the temperature of molten aluminum during metal die casting.

Bath Type Low Pressure Casting Holding Furnace

Bath Type Low Pressure Casting Holding Furnace Equipment Characteristics ◆ The furnace body bears high pressure and high strength. The furnace shell is welded by high strength steel plate. When the test pressure is 0.25 MPa, there is no deformation on the shell. ◆The sealing performance of the furnace body is great. The furnace cover, door and rod connection are reliably sealed with the furnace body, and there is not gas leaks. ◆ No crucible loss. Non-metallic aluminium melt pool, no crucible loss, low use and maintenance costs. ◆ Liquid aluminum does not increase iron. Non-metallic molten pool, aluminum liquid without iron hyperplasia and other pollution. ◆ The melt pool has a long service life. The molten pool is casted with low cement castable for aluminum alloy, which is resistant to aluminum liquid erosion and has a service life of more than 3 years. ◆ Good insulation performance. The lining insulation adopts high-quality insulation materials such as silicon-calcium plate and nano-plate, and the temperature rise of the furnace shell surface is less than 60 °C. ◆ High temperature control precision. With the intelligent temperature control instrument and aluminum temperature thermocouple, the double loop control of aluminum liquid and furnace temperature is realized, and the temperature control accuracy reaches ± 2℃.

Bath Type Melting Furnace Equipment Features ◆ The molten pool is formed by integral injection molding with non-infiltrative and high-strength injection-resistant material (Allied Mineral), and the molten pool does not adhere to aluminum, which slows down the formation of corundum tumor. ◆ Non-metallic molten pool, liquid aluminum without iron hyperplasia and other pollution. ◆ The melt hearth service live is more than 3 years. ◆ The furnace village adopts multi-layer anti-leakage technology, without the consideration of aluminum liquid ' string leakage ' lining. ◆ The furnace cover has a cylinder rotating lift, which is convenient for molten pool cleaning, slag removal operation, furnace cover and electric heating element maintenance. ◆ It has a variety of safety protection such as aluminum liquid over-temperature alarm and furnace over-temperature alarm.

Count Pressure Casting Holding Furnace

Count Pressure Casting Holding Furnace The electrical type counter pressure furnace is made of high-quality electrical resistance wire as heating element. The furnace lining is composed of fiber module and fiber blanket, which has less heat storage and good heat preservation performance. The crucible furnace is suitable for graphite crucible. The crucible has good high temperature oxidation resistance and can be used for melt insulation before differential pressure casting. The crucible furnace is equipped with a power plug, which can be conveniently, safely and reliably connected with the power socket on the counter pressure casting machine.

MESSAGE

We will contact you within one working day. Please pay attention to your email.